|

|

|

|

|

|

|

One 3 and 3/4 wheel 1993 Integra! |

|

|

|

|

|

|

|

|

|

|

|

|

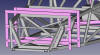

The steel I-beam frame welded! God I love stick welding. The feeling of power! |

|

|

|

|

|

|

|

|

|

|

|

|

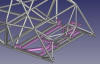

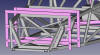

Top frame sitting on the support frame. Shims allow easy levelling. |

|

|

|

|

|

|

|

|

|

|

|

Top frame sitting on the support frame. Shims allow easy levelling. |

|

|

|

|

|

|

|

|

|

|

|

Finally finished! Dead level and flat! |

|

|

|

|

|

|

|

|

|

|

|

|

How do you get a motor and gearbox out of an Integra? Chop the front of the car off of course! |

|

|

|

|

|

|

|

|

|

|

|

Motor and gearbox out and on the deck courtesy of Harbor Freight! Pleasently surprised as to the quality of their One Ton lift! |

|

|

|

|

|

|

|

|

|

|

|

The motor and gearbox where they need to be ... on the table! |

|

|

|

|

|

|

|

|

|

|

|

|

And completely stripped, inside and out! |

|

|

|

|

|

|

|

|

|

|

|

Lots of lovely parts to play with. |

|

|

|

|

|

|

|

|

|

|

|

Manifold dropping under the sump... |

|

|

|

|

|

|

|

|

|

|

|

|

... and out the back with the offending gearbox selector input shaft. |

|

|

|

|

|

|

|

|

|

|

|

Front of the engine - nice and easy as all belts are seperate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

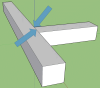

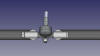

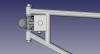

The final gearshift design! |

|

|

|

|

|

|

|

|

|

|

|

|

The final gearshift design! |

|

|

|

|

|

|

|

|

|

|

|

Gear lever from a Lotus 35 |

|

|

|

|

|

|

|

|

|

|

|

Digital level and angle finder |

|

|

|

|

|

|

|

|

|

|

|

|

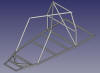

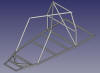

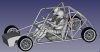

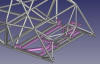

FreeCad Basic Midlana Chassis |

|

The Basic Chassis modelled up with FreeCAD. |

|

|

|

|

|

|

|

|

|

Welding Cart finished off in the brightest yellow I could find |

|

|

|

|

|

|

|

|

|

|

|

Official start - Dec. 24th, 2017! |

|

|

|

|

|

|

|

|

|

|

|

|

The first cut! Section 300 cut and on the table! Cat inspected and approved! |

|

|

|

|

|

|

|

|

|

|

|

Four done! A friend lent me a quality bandsaw which makes the cuts soooo easy! |

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Chassis cutting and measuring complete. 9 hours start to finish. |

|

|

|

|

|

|

|

|

|

|

|

Front end corrected and adapted for in-board suspension |

|

|

|

|

|

|

|

|

|

|

|

Testing my welding - prepare for pain! |

|

|

|

|

|

|

|

|

|

|

|

|

|

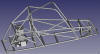

Base chassis all tacked up. Square, symetrical and level. Result! |

|

|

|

|

|

|

|

|

|

|

|

Obligatory test drive along with "vroom vroom" noises! |

|

|

|

|

|

|

|

|

|

|

|

|

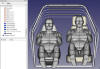

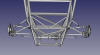

Virtual chassis after 19 Jan 2017. Chassis heightened to accomodate me! |

|

|

|

|

|

|

|

|

|

|

|

Side view of virtual Chassis |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

How many options on roll-cage can you have???? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest version of the Virtual Chassis. Liking it! |

|

|

|

|

|

|

|

|

|

|

|

Front suspension fixture looking good! |

|

|

|

|

|

|

|

|

|

|

|

|

Rear suspension fixture - that was a bear! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Virtual world coming on nicely! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roll hoop fabbed and in place! Beep you bastard! |

|

|

|

|

|

|

|

|

|

|

|

One Midlana Suspension kit! |

|

|

|

|

|

|

|

|

|

|

|

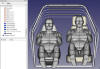

While it's easy to work with I'm not sure I trust these new plastic roll cages. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Wooden frame to make mounting the roll cage easier. |

|

|

|

|

|

|

|

|

|

|

|

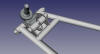

Early draft A Arms. Yurns out that while these were simple, the geometry was all wrong! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Final design for the lower A Arms |

|

|

|

|

|

|

|

|

|

|

-800.jpg)

|

|

|

|

Scaffolding makes holding things in place and measuring in 3D space SOOOO much easier! |

|

|

|

|

|

|

|

|

-800.jpg)

|

|

|

|

Getting a grip on the way the bars work in 3D space in PVC made mistakes much cheaper. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Look who remembered to put the seat belt anchors in before welding the roll hoop. I cannot imagine trying to do these after the tubes were welded in. |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

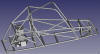

Finally! A 3D Chassis! Damn that was a lot of work! |

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

"Drivers Cell" complete with door bars |

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

The obligatory "scaffolding" holding everything in place. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front suspension fixture under fabrication. |

|

|

|

|

|

|

|

|

|

|

|

Front suspension fixture completed and in place |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Rear suspension fixture completed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Automotive pornogrpahy... $164 of AN-8 bolys from Aircraft Spruce |

|

|

|

|

|

|

|

|

|

|

|

Tthreaded into the tubes in the front fitment. |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Working out the angle for the front vertical. |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

CAD! (Cardboard Aided Design) |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Transferred to 3/16" steel |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Getting the angle spot on! |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

The vertical completed. Looks like a medieval torture device... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

More woodwork. Jig for the rear subframe. |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Everything in it's place. |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Finished (almost) article! |

|

|

|

|

|

|

|

|

|

|

|

|

More woodwork, for fat bottomed girls. |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Jig for the rear end upper bars. |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Rear upper bars tacked in! |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Jig to hold the rear subframe in place - note the error |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

First effort at reaming suspension bolt holes! Allright! :-)

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

First go at a suspension bracket... |

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

... and a finished job ... |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Bollocks! 7/16" washers actually had an internal diameter of 0.513" so the bolt's as loose as a tarts underwear! |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Front end all setup for welding! |

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Fitting the engine and the rear subframe. |

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Rear subframe all mounted! |

|

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Nifty little jacks made from angle iron and a bolt welded to it enable accurate placement of the motor and transmission

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

If at first you dont succeed. |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Rear lower suspension mounts! |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Rear lower suspension mount.

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Ooooooh! Pressies from Summit Racing! |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Look at all that shiny loveliness! |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Motor mount - drivers side |

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Seat mount - drivers side |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Getting the front end of the chassis all welded in and "linished" |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Making a little room for the steering column |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

The plan of the modified front lower wishbone... |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

... which became the jig... |

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

... which became cut metal... |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

... which became a lower wishbone! |

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

First pieces I've machined in nearly 40 years! |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

The insert get pushed into the retainers at the end of the lower wishbone. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

The M16 (*ahem*) rod end! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Welding distortion... :-( |

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Two completed lower front wishbones. |

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Starting to come together... |

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Everything where it should be! |

|

|

|

|

|

|

|

|

|

|

|

|

|

.JPG)

|

|

|

|

Rear suspension complete too! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-800.jpg)

-800.jpg)

-800.jpg)

-800.jpg)

-800.jpg)

-800.jpg)

-800.jpg)

.jpg)